Learn how we implement planned preventative maintenance across a range of sectors and industries for a safer environment for all.

What is Planned Preventative Maintenance (PPM)?

Planned Preventative Maintenance (PPM) is a proactive approach to maintenance within commercial and industrial settings to ensure future-proof buildings and to comply with health and safety regulations.

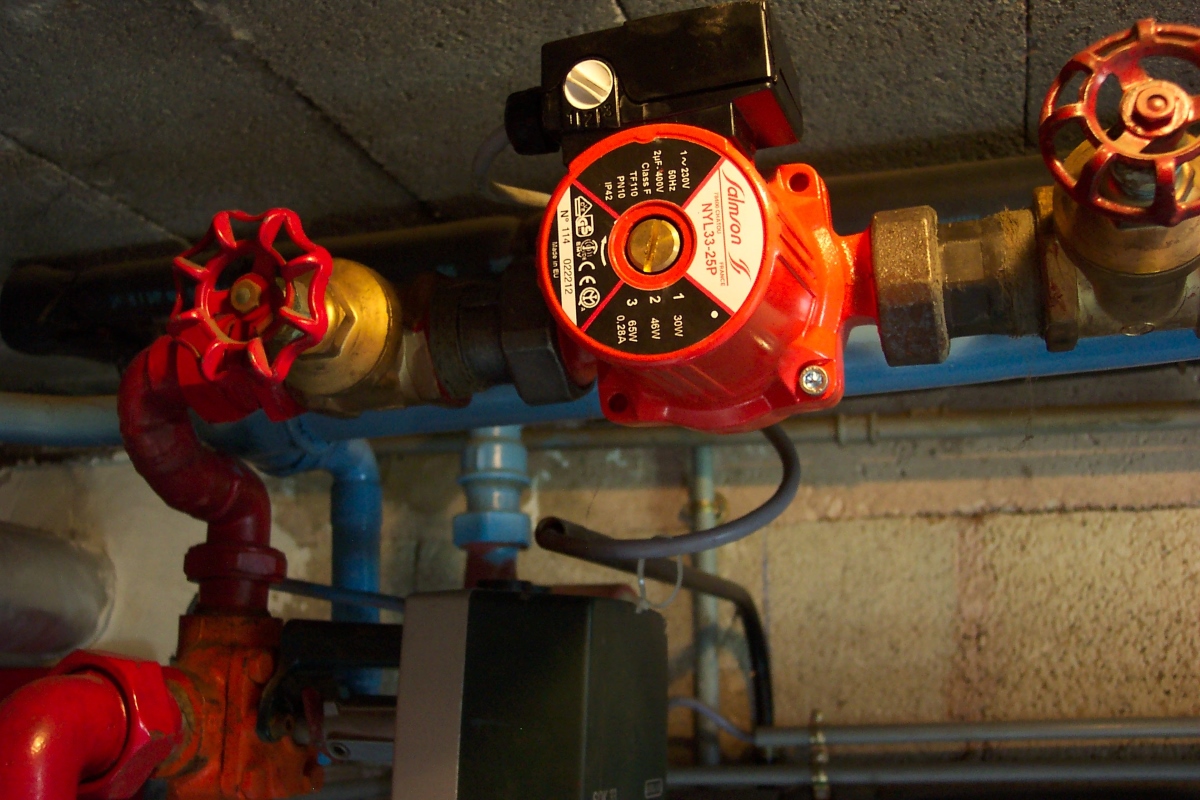

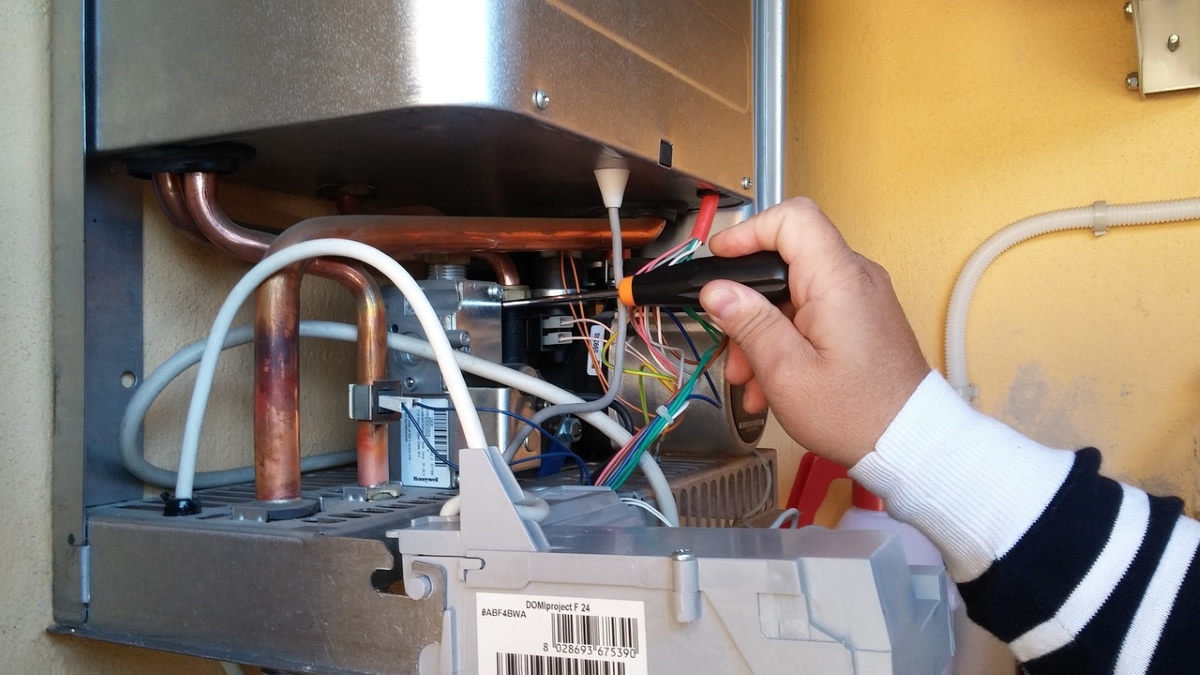

PPM involves scheduling and performing regular inspections, repairs, and upkeep tasks on equipment, machinery, or facilities to prevent unexpected breakdowns and ensure their continued efficient operation.

Essentially, the primary goal of PPM is to identify and address potential issues before they escalate into more significant problems.

What Does Planned Preventative Maintenance Consist of?

A preventative maintenance plan consists of an array of factors, all carefully curated to ensure there has been every step taken to reduce risk of incident within particular premises.

There are some particular aspects that are typical to a PPM plan, these include, but aren’t limited to:

- Scheduled inspections of facilities and equipment

- Scheduled maintenance of facilities and equipment

- Predictive maintenance

- Records of maintenance activities / issues

- Compliance with industry standard and policy

The overall goal is to keep everybody involved in the facility as safe as possible and by keeping up to date with maintenance and fixing potential issues before they arise makes for a safer working environment.

Frequently Asked Questions

How do you create a preventative maintenance plan?

Creating an effective preventative maintenance plan involves identifying critical equipment, gathering relevant information, and assessing associated risks and ultimately, only an experienced team of professionals can do this.

There needs to be specific maintenance tasks, established schedules, and necessary resources allocated, and implement monitoring techniques to identify potential issues proactively.

What is the difference between reactive maintenance and planned preventative maintenance?

Reactive maintenance means to fix equipment and issues once it has broken, while PPM strives to prevent the issues from happening.

Why is Planned Preventative Maintenance (PPM) preferable to reactive maintenance?

Planned Preventative Maintenance (PPM) is preferable to reactive maintenance because it focuses on scheduled, proactive tasks aimed at preventing equipment failures. Reactive maintenance involves addressing issues only after they occur, leading to downtime, higher repair costs, and potential disruptions to operations.

PPM aims to reduce these downtimes by being predictive and prepared.

Planned Preventative Maintenance Projects

Planned Preventative Maintenance Locations

- North London

- South London

- West London

- East London

- Kent

- Essex

- Hampshire

- Central London

- Greater London

- Surrey

- Sussex

- Berkshire

- Buckinghamshire

- Hertfordshire